Business Overview

comprehensive technologies including surface treatment and

line services to provide surface treatment systems

that aim to be both environmentally and economically friendly.

- Pretreatments

- Functional coatings

Automotives and industrial fields

Feature: Environmentally friendly conversion coatings to replace zinc phosphate coatings

-

Reducing substances that place a

burden on the environmentHeavy metals, conversion sludge

-

Shorter process

Cost reduction, time reduction

-

Superior corrosion resistance

Long-term rust inhibition

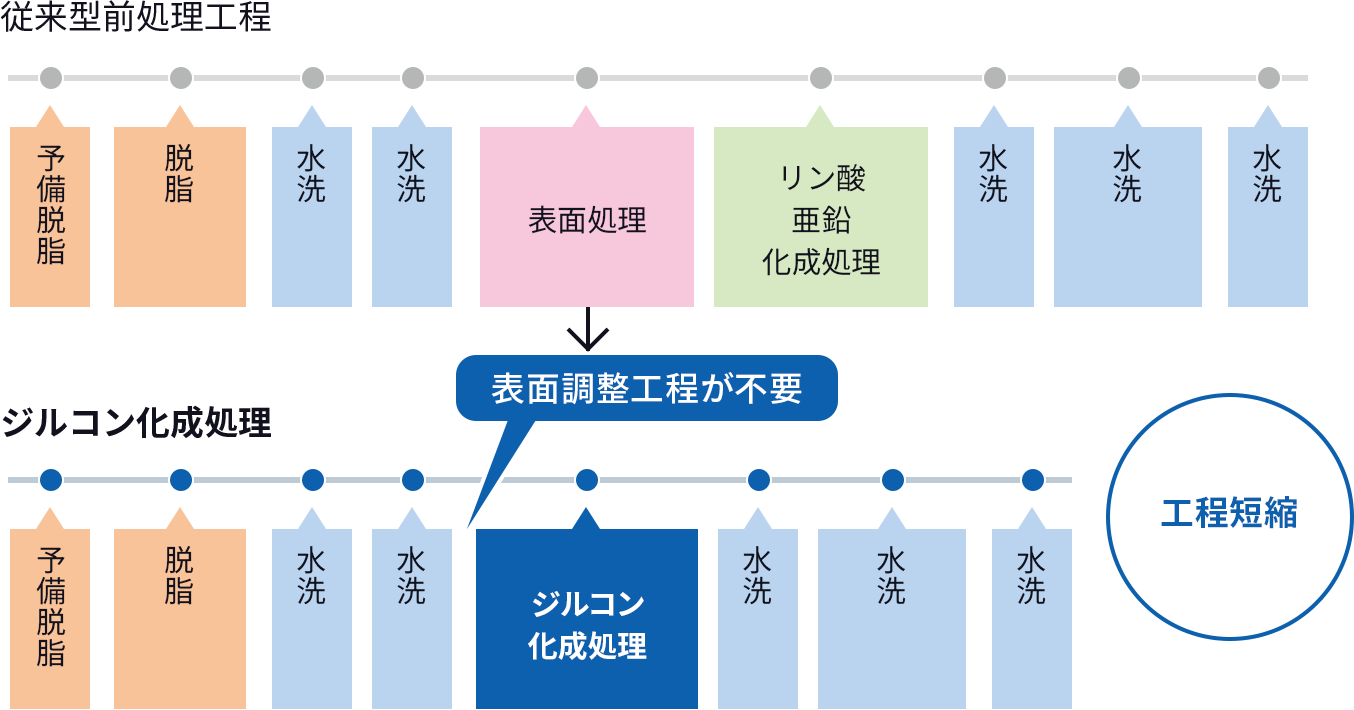

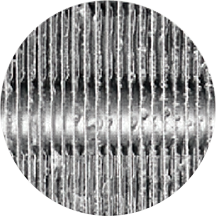

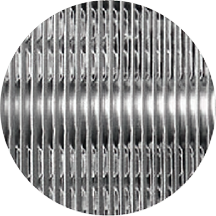

Difference in coating properties

| Conventional zinc phosphate conversion process | Zirconium conversion treatment | |

|---|---|---|

| Coating appearance (SEM) |

|

|

| Coating structure | Metal phosphate crystal coating | Amorphous metal oxide film |

| Adhesion | Anchor effect between the formed crystalline coating and the applied coating | Chemical bond with the applied coating resin due to the introduction of an adhesive functional film |

| Corrosion resistance | Alkaline buffer / self-repair | A fine structure with low porosity that is less prone to permeation by corrosive substances |

| Coating weight | 1.0-2.0g/m2 | 0.05-0.10g/m2 |

| Process before conversion | Activation process is required | Not required |

| Environmental burden | Phosphate, nickel, manganese | Nothing of note |

Differences in the treatment process

Products

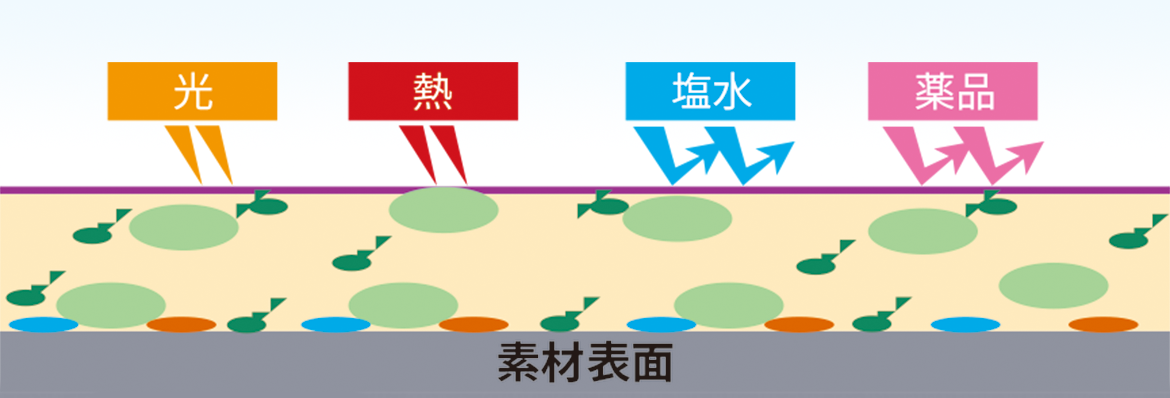

Function endowment by thin film

-

Adhesion

Improved adhesion between the steel plate and the applied coating

-

Corrosion resistance

Long-term rust inhibition of the steel plate in a corrosive environment

-

Weather resistance

Inhibition of coating degradation due to UV rays in outdoor use

-

Chemical resistance

Superior in acid and alkali resistance

-

Sliding

Inhibition of coating surface damage due to physical loads

Zinc plating and non-ferrous metallic coils

-

- Building uses

-

-

- Home appliance uses

-

-

- Laminate uses

-

Function-endowing design technology

- Synthetic resin technology

- Inorganic component dispersion technology

- Organic/inorganic composite technology

- Treatment liquid stabilization technology

- Surface tension control technology

- Fast low-temperature film-forming technology

- Coating physical property control technology

Products

Treatments for aluminum beverage cans

Aluminum is very susceptible to oxidization. The following is required to use it as a container for beverages.

-

Removal of

oxidized layer (rust) -

Removal of grime deposited

during forming -

Prevention of reoxidation

after rinsing

Summary of the aluminum beverage can

treatment process

- Degrease

-

Conversion

Coatings -

Rinse and

drying

Functions of our chemicals

-

- Degreasing agents

-

The surfaces of aluminum cans after the forming process have deposits of rust and oil-based grime, and our products function to remove these.

-

- Conversion agents

-

Aluminum is a metal that is susceptible to corrosion. Our products function to form a metallic coating that endows the aluminum can surfaces with functions such as corrosion resistance and coating adhesion.

Products

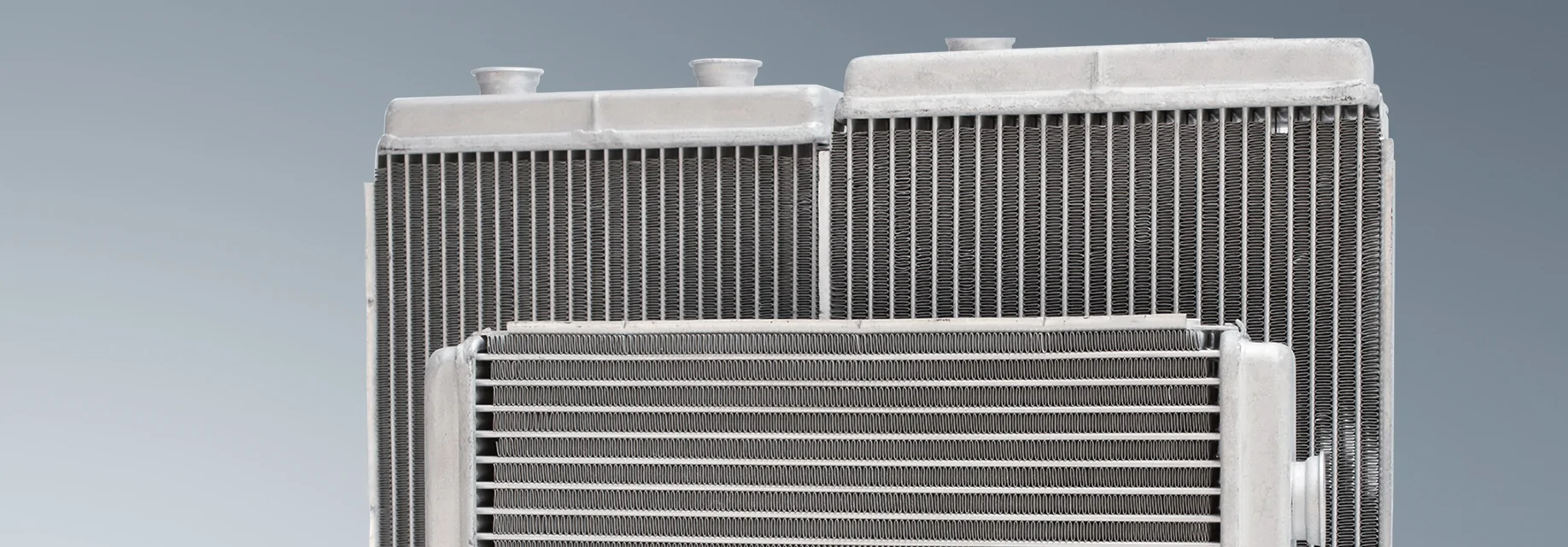

Functional coatings

A hydrophilic treatment type suitable for the type of heat exchanger is available

- Automobile air conditioner

-

- Post-coating

-

Hydrophilic treatment of a completed

heat exchanger - Extra features

- Anti-odor

Comfortable even in the cabin, a compact space. - Room air conditioner

-

- Pre-coating

-

Hydrophilic treatment of aluminum plates

before making heat exchangers - Extra features

- Workability and soiling

Remains hydrophilic even when working fluid is deposited.

Condensation clogging is mitigated with our hydrophilic treatment

-

- Before

-

Endowed with our technology for water leakage

Endowed with our technology for water leakageCondensation clog formed

-

- After

-

Heat ex-

Heat ex-

change rate

improvedCondensation clog unclogged

Prevent condensate that forms during

cooling from clogging the fins (condensation clogging)

on the heat exchanger and

decreasing cooling efficiency.

- Required performance

- Prevent condensation clogging between heat exchange fins

Heat exchange efficiency is improved and condensation clogging is mitigated.

Products

- Contact Us Contact us about Business Overview