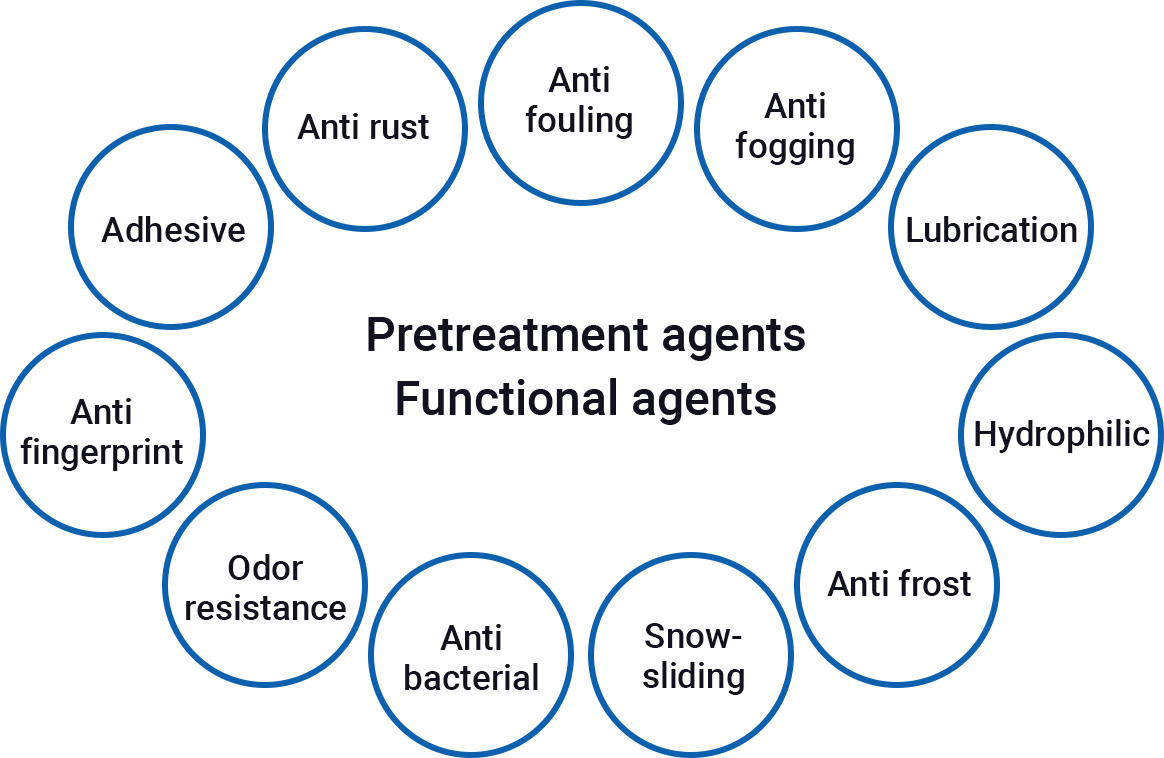

Functions of Surface Treatments

Pretreatments and functional coatings endow automotive and general industrial products,

steel, beverage cans, and various other materials with functions.

Functional Agents

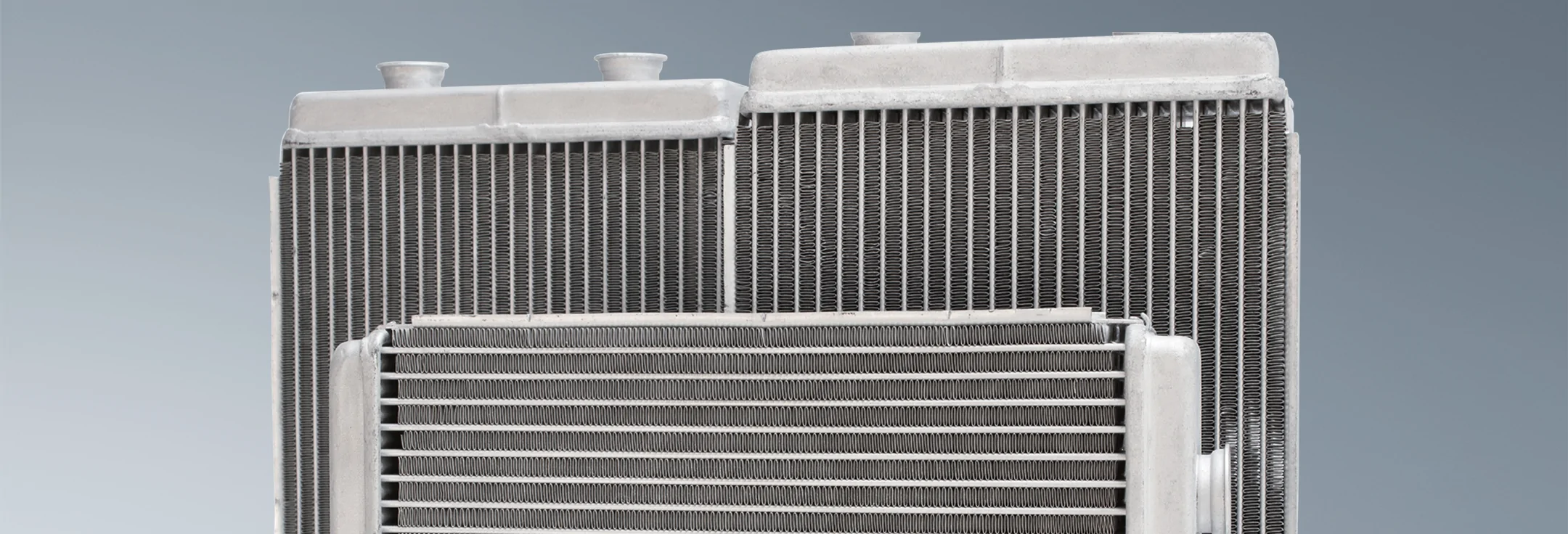

Hydrophilic treatments

We have two types of hydrophilic coatings for heat exchangers: the pre-coating type for treating the aluminum plate for heat exchangers and the post-coating type for treating the heat exchanger itself. Hydrophilic coatings prevent bridges of condensate between the fins by making the surface of the heat exchanger hydrophilic, which prevents the reduction of cooling efficiency. The special resin provides good hydrophilicity and reduces odor from the evaporator with its low-adsorption property. Rust prevention can be improved by using it with primer. We will consider improved products with your input.

Aluminum Fin Process

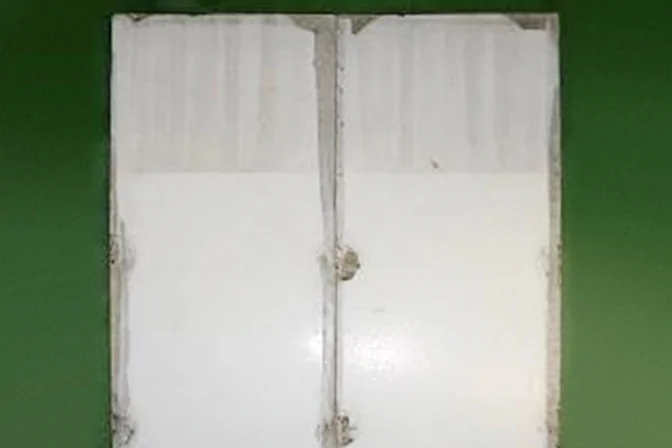

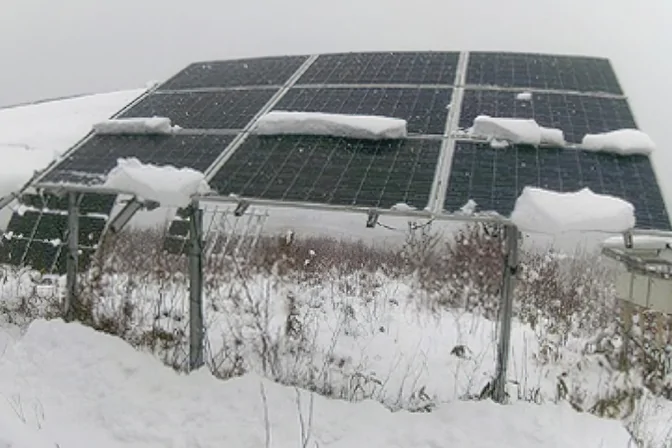

Self-cleaning / snow-sliding / anti-fogging treatments

The coating endows the material with various functions, including self-cleaning, snow-sliding, and anti-fogging

-

- Self-cleaning effect

-

-

- Snow-sliding effect

-

-

- Anti-fogging effect

-

Special

Feature

Degreasing agents

Removes grease from the material surface and assists the formation of coatings

| Compatible materials |

Features | Product Name | Appearance | Application | Standard Condition | Pictograms | ||

|---|---|---|---|---|---|---|---|---|

| Temp. (°C) | Time (sec.) | Dry Temp. (°C) | ||||||

| Aluminum Coil (For Beverage Can End / Aluminum Fin) |

Middle Alkaline (P.N. Free) |

SURFCLEANER EC370 series |

Powder | Spray Dip |

50-80 | 2-30 | - | 58 |

| Aluminum coil, foil (For Lithium Ion Battery Packaging) |

Weak Alkaline (P.N. Free) |

SURFCLEANER EC371 |

Powder | Spray Dip |

50-80 | 2-30 | - | 58 |

Pictograms may vary by product. Please contact us for details.

Etching Agent

Etches the material surface and assists the formation of coatings

| Compatible materials |

Features | Product Name | Appearance | Application | Standard Condition | Pictograms | ||

|---|---|---|---|---|---|---|---|---|

| Temp. (°C) | Time (sec.) | Dry Temp. (°C) | ||||||

| Aluminum coil (for can) | Strong Alkaline | SURFCLEANER 420N-2 |

Liquid | Spray Dip |

50-70 | 2-30 | - | 58 |

Pictograms may vary by product. Please contact us for details.

Primer / Conversion Coatings

Improves the corrosion resistance of the base material surface and the adhesion with the hydrophilic coating

| Compatible materials |

Features | Product Name | Appearance | Application | Standard Condition | Pictograms | ||

|---|---|---|---|---|---|---|---|---|

| Temp. (°C) | Time (sec.) | Dry Temp. (°C) | ||||||

| Aluminum Coil (Aluminum Fin) |

Resin | SURFALCOAT 455 |

Liquid | Coater | RT | 5-30 | 180-220 | 89 |

| Aluminum Coil (for can cap (applied roll coater)) |

Non Chromate | SURFCOAT 147/148 |

Liquid | Coater | RT | - | 50-100 | 58 |

| Aluminum coil, foil (for lithium-ion battery packaging and laminated products (applied roll coater)) | Chromate (Trivalent) |

SURFCOAT NR-X |

Liquid | Coater | RT | 5-30 | 80-230 | 5 |

| Aluminum coil (for lithium-ion battery packaging and laminated products (applied roll coater)) | Non Chromate | SURFCOAT EC1000 series |

Organic/ Inorganic |

Coater | RT | 5-30 | 80-230 | 9 |

| Aluminum Coil (For Beverage Can End / Aluminum Fin) |

Chromic-Phosphoric Acid | ALSURF 401/45 |

Liquid | Spray Dip |

30-60 | 5-30 | 50-100 | 589 |

Pictograms may vary by product. Please contact us for details.

Hydrophilic Coatings

Forms a hydrophilic coating and endows the material surface with hydrophilicity

| Compatible materials |

Features | Product Name | Appearance | Application | Standard Condition | Pictograms | ||

|---|---|---|---|---|---|---|---|---|

| Temp. (°C) | Time (sec.) | Dry Temp. (°C) | ||||||

| Aluminum Coil (Aluminum Fin) |

Resin | SURFALCOAT 160 |

Liquid | Coater | RT | 5-30 | 180-220 | 8 |

| Aluminum Coil (Aluminum Fin) |

Resin | SURFALCOAT 9300 series |

Liquid | Coater | RT | 5-30 | 180-220 | 9 |

| Aluminum component (for automotive heat exchanger) |

Organic/ Inorganic |

SURFALCOAT 1500 |

Liquid | Coater | RT | 5-30 | 150-170 | 89 |

Pictograms may vary by product. Please contact us for details.

General-purpose hydrophilic coatings

Hydrophilic coatings can be formed with ease on various base materials when applied

| Compatible materials |

Features | Product Name | Appearance | Application | Standard Condition | Pictograms | ||

|---|---|---|---|---|---|---|---|---|

| Temp. (°C) | Time (sec.) | Dry Temp. (°C) | ||||||

| Glass, resins, metals, etc. | Organic/ Inorganic |

SURFCOAT AF series |

Liquid | Coater | RT | 5-30 | RT | 289 |

Pictograms may vary by product. Please contact us for details.

-

-

-

- Explosives

- Self-reactive

- Organic peroxides

-

-

-

-

- Flammable

- Self-reactive

- Self-heating

-

-

-

-

- Oxidising

- Organic peroxides

-

-

-

-

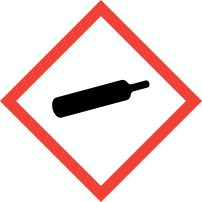

- Gases under pressure

-

-

-

-

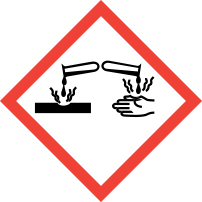

- Corrosive to metals

- Skin corrosion

- Irritation serious eye damage

-

-

-

-

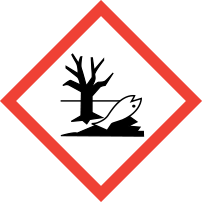

- Hazardous to the aquatic environment

-

-

-

-

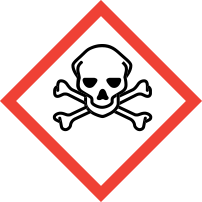

- Acute toxicity

-

-

-

-

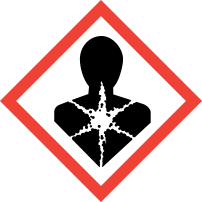

- Germ cell mutagenicity

- Carunogenicity

- Toxic to reproduction

- Respiratory sensitizer

- Specific target organ toxicity

- Aspiration hazard

-

-

-

-

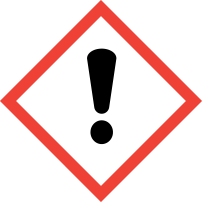

- Acute toxicity

- Skin irritation

- Eye irritation

- Skin sensitizer

- Specific target organ toxicity

-

- Contact Us Contact us about Products